Crafting Precision, Delivering Quality

Precision Custom Mold Bases

Experience Superior Craftsmanship

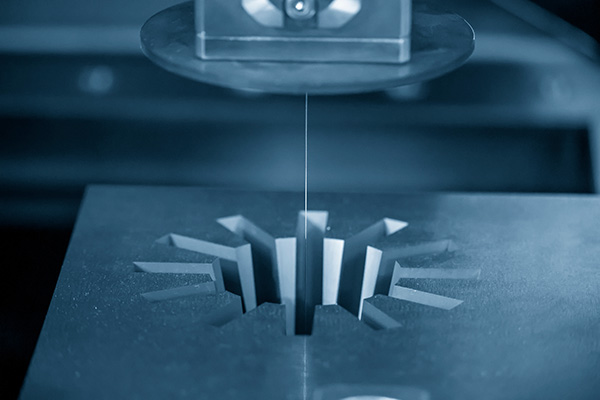

Precision Wire EDM Services

Discover the exceptional quality and precision of our custom machining services. Our team of skilled experts is dedicated to delivering top-notch solutions tailored to your specific needs. Contact us today to learn how we can bring your vision to life with unparalleled craftsmanship and attention to detail.

Precision Wire EDM Services

Crafting Consistency and Reliability

Our Precision Wire EDM Services utilize advanced technology to deliver exceptionally precise machining solutions. Wire Electrical Discharge Machining (EDM) is a cutting-edge process that uses electrical discharges (sparks) to precisely shape and contour materials. This method is ideal for creating intricate and complex shapes with tight tolerances, where traditional machining techniques may not be feasible. At Custom Mold Services, we specialize in harnessing the power of Wire EDM to produce high-quality components that meet the most exacting specifications. Whether you need prototypes, small batches, or large-scale production runs, our expertise in Precision Wire EDM ensures superior accuracy and consistency in every part we manufacture.

Understanding Wire EDM

Wire EDM involves using a thin, electrically charged wire to create cuts in the workpiece by generating controlled electrical discharges (sparks) between the wire and the material. This non-contact machining method allows us to cut through conductive materials with high precision, regardless of their hardness or complexity. Key features of Wire EDM include:

- High Precision: Wire EDM can achieve tolerances as tight as ±0.0001 inches (±2.5 microns), making it suitable for producing parts with intricate details and exacting specifications.

- Complex Shapes: The technology excels in cutting complex shapes, intricate contours, and sharp corners that may be challenging or impossible to achieve with conventional machining methods.

- Minimal Material Stress: Because Wire EDM does not require direct contact between the cutting tool and the workpiece, it minimizes mechanical stress and distortion on delicate materials, preserving their integrity.

The Advantages of Choosing Precision Wire EDM Services

Exceptional Accuracy and Consistency:

Our Precision Wire EDM Services ensure that every part meets stringent quality standards with consistent accuracy across production runs. Whether you need one-off prototypes or large-scale production, we deliver superior results that exceed expectations.Versatility in Material Compatibility:

From exotic alloys and hardened steels to aluminum, titanium, and more, Wire EDM can process a wide range of conductive materials with ease, maintaining high precision and surface finish quality.Cost-Effective Solutions:

Despite its advanced capabilities, Wire EDM offers cost-effective solutions by reducing the need for secondary operations, minimizing material waste, and optimizing production efficiency.Rapid Prototyping and Production:

With fast setup times and efficient machining processes, we offer rapid prototyping and quick turnaround times for production runs, ensuring timely delivery of your components.

Applications of Precision Wire EDM

Precision Wire EDM finds extensive application in various industries where intricate components and exacting specifications are essential, including:

- Aerospace: Manufacturing turbine components, aerospace gears, and intricate parts for aircraft engines that demand high reliability and precision.

- Medical: Producing surgical instruments, orthopedic implants, and medical device components with precise dimensions and biocompatible materials.

- Automotive: Creating injection molds, tooling components, and precision parts for automotive engines and transmissions that require durability and accuracy.

- Electronics: Machining intricate parts for semiconductor manufacturing equipment, connectors, and electrical components with high precision and consistency.

Our Commitment to Excellence

At Custom Mold Services, we are committed to delivering excellence in every aspect of our Precision Wire EDM Services. We invest in state-of-the-art EDM machinery, employ skilled engineers and machinists, and adhere to rigorous quality control processes to ensure the highest standards of craftsmanship and performance.

Partner with Us for Your Machining Needs

Choosing Custom Mold Services means partnering with a trusted industry leader in Precision Wire EDM. Whether you require custom prototypes, complex parts, or large-scale production, we have the expertise and capabilities to meet your machining needs with precision, efficiency, and reliability. Contact us today to discuss your project requirements and discover how we can help you achieve success with our Precision Wire EDM Services.

Contact Us Today

Ready to experience the precision and reliability of our Precision Wire EDM Services? Contact us today to speak with one of our knowledgeable team members. We are here to provide you with tailored solutions that meet your specific machining needs and exceed your expectations for quality and service.

At Custom Mold Services, we are dedicated to pushing the boundaries of what is possible with Precision Wire EDM. Contact us today and discover why we are the preferred choice for precision machining solutions across various industries.