Crafting Precision, Delivering Quality

Precision Custom Mold Bases

Experience Superior Craftsmanship

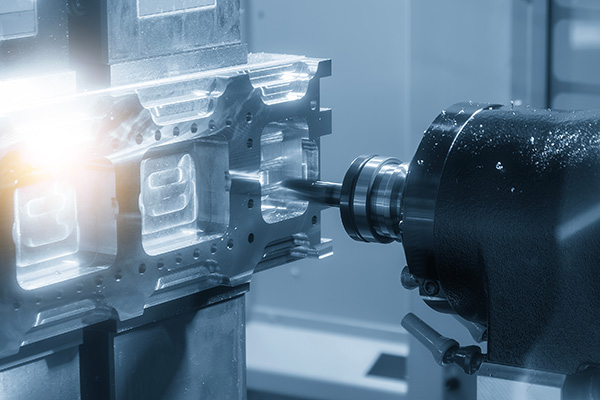

Expert Horizontal CNC Machining

Discover the exceptional quality and precision of our custom machining services. Our team of skilled experts is dedicated to delivering top-notch solutions tailored to your specific needs. Contact us today to learn how we can bring your vision to life with unparalleled craftsmanship and attention to detail.

Expert Horizontal CNC Machining

Crafting Consistency and Reliability

At Custom Mold Services, we specialize in Expert Horizontal CNC Machining, offering advanced solutions that optimize precision, efficiency, and quality in custom machining. Our horizontal machining capabilities are designed to meet the demands of modern manufacturing, allowing us to deliver superior results for complex and high-precision components.

Understanding Horizontal CNC Machining

Horizontal CNC Machining involves positioning the workpiece horizontally on the machining center, allowing for machining operations on multiple sides of the part in a single setup. This setup offers several advantages over traditional vertical machining, including:

- Improved Efficiency: By minimizing the need for multiple setups and repositioning of the workpiece, horizontal machining reduces cycle times and enhances productivity.

- Enhanced Precision: The horizontal orientation allows for more stable machining conditions, resulting in greater accuracy and consistency in part dimensions and surface finishes.

- Complex Part Capabilities: Horizontal machining centers are ideal for machining complex geometries, contours, and features that require machining on multiple sides or angles.

The Benefits of Choosing Horizontal CNC Machining

Versatility in Machining:

Our horizontal machining capabilities enable us to handle a wide range of materials and part sizes, from small, intricate components to large, heavy-duty parts. This versatility ensures that we can accommodate diverse industry needs and project requirements.Superior Surface Finishes:

The stable machining environment provided by horizontal CNC machining centers allows for finer surface finishes, meeting the high aesthetic and functional standards required in industries such as aerospace, automotive, and medical.Cost Efficiency:

Reduced setup times and increased throughput contribute to overall cost savings for our clients. Horizontal machining minimizes idle time and maximizes machine utilization, translating to competitive pricing and faster turnaround times.Scalability and Consistency:

Whether you need a single prototype or large-volume production, our horizontal machining capabilities are scalable to meet your demands without compromising on quality or precision. Consistency in part quality is maintained throughout the production process.

Applications of Horizontal CNC Machining

Horizontal CNC Machining is widely utilized across various industries for the production of critical components and parts, including:

- Automotive: Manufacturing engine blocks, transmission components, and chassis parts with precise tolerances and complex geometries.

- Aerospace: Producing structural components, turbine blades, and aerospace-grade alloys with stringent requirements for strength, durability, and performance.

- Medical: Machining surgical instruments, orthopedic implants, and medical device components that demand biocompatibility and precision.

- Electronics: Creating intricate parts for electronic devices and semiconductor equipment with precise tolerances and smooth surface finishes.

Our Commitment to Quality and Innovation

At Custom Mold Services, quality and innovation are at the core of everything we do. We invest in state-of-the-art horizontal machining technology and maintain a team of skilled engineers and machinists dedicated to pushing the boundaries of what’s possible in custom machining. Our commitment to continuous improvement ensures that we stay ahead of industry trends and deliver cutting-edge solutions that meet and exceed our clients’ expectations.

Partner with Us for Exceptional Results

Choosing Custom Mold Services for your horizontal CNC machining needs means partnering with a team that is committed to excellence. Whether you require precision machining of intricate components or high-volume production of complex parts, we have the expertise and capabilities to deliver superior results. We work closely with our clients to understand their unique requirements and provide customized solutions that optimize performance and efficiency.

Contact Us Today

Ready to experience the advantages of Expert Horizontal CNC Machining for your next project? Contact us today to discuss your machining requirements with our team of experts. We are here to provide you with the best solutions tailored to your specific needs and industry standards. Let us help you achieve success with precision, efficiency, and reliability.

At Custom Mold Services, we are dedicated to advancing the possibilities of custom machining through Expert Horizontal CNC Machining. Reach out to us today and discover how our advanced capabilities can elevate your manufacturing operations and propel your business forward.