Crafting Precision, Delivering Quality

Precision Custom Mold Bases

Experience Superior Craftsmanship

Manifolds for Plastic Injection Molding

Discover the exceptional quality and precision of our custom machining services. Our team of skilled experts is dedicated to delivering top-notch solutions tailored to your specific needs. Contact us today to learn how we can bring your vision to life with unparalleled craftsmanship and attention to detail.

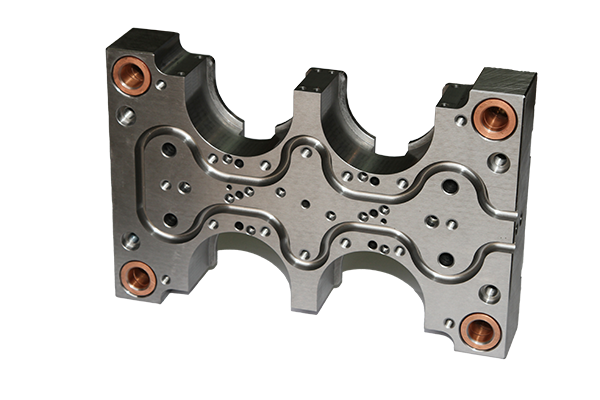

Manifolds for Plastic Injection Molding

Crafting Consistency and Reliability

Our expertise in manufacturing Manifolds for Plastic Injection Molding ensures efficient and reliable performance in your injection molding processes. These manifolds are crucial components that distribute molten plastic to multiple mold cavities, optimizing production efficiency and reducing cycle times. At Custom Mold Services, we specialize in custom designing and fabricating manifolds that meet the specific needs of your injection molding operations. Whether you require hot runner systems for precise temperature control or cold runner manifolds for cost-effective molding, our solutions are engineered to enhance productivity and maintain quality throughout your manufacturing process.

Understanding Manifolds for Plastic Injection Molding

Manifolds play a critical role in plastic injection molding by evenly distributing molten plastic to multiple mold cavities. This ensures consistent part quality, reduces cycle times, and optimizes production efficiency. Key aspects of our manifold manufacturing capabilities include:

- Custom Design and Engineering: We collaborate closely with our clients to understand their specific molding requirements and design custom manifold solutions tailored to their needs. Our engineering team utilizes advanced CAD/CAM software to optimize manifold designs for maximum efficiency and performance.

- Hot Runner Systems: We specialize in designing and manufacturing hot runner systems that maintain precise temperature control, minimize material waste, and facilitate faster cycle times. Our hot runner manifolds are crafted from high-quality materials to withstand the demands of continuous operation.

- Cold Runner Manifolds: For applications that require cost-effective molding solutions, we offer cold runner manifold designs that help reduce material usage and tooling costs while maintaining part quality and consistency.

The Benefits of Choosing Our Manifolds

Enhanced Efficiency:

Our manifold solutions are engineered to enhance production efficiency by optimizing material flow and reducing downtime associated with mold changeovers.Precision and Quality:

We uphold strict quality control measures throughout the manufacturing process to ensure that each manifold meets precise dimensional tolerances and performance specifications.Versatility in Applications:

Our manifold solutions cater to a wide range of plastic injection molding applications, including automotive parts, consumer goods, medical devices, and more. Whether you need small-scale prototypes or large-scale production runs, we have the capabilities to meet your needs.Industry-Leading Expertise:

With years of experience and a deep understanding of injection molding processes, we are trusted by leading companies across industries to deliver reliable, high-performance manifold solutions.

Real-World Applications of Manifolds for Plastic Injection Molding

Our Manifolds for Plastic Injection Molding are utilized in various industries:

- Automotive: Manufacturing precision components such as dashboards, interior trim, and exterior parts that require high strength and durability.

- Medical: Producing medical device components and packaging solutions that meet stringent regulatory requirements for safety and performance.

- Consumer Goods: Crafting household appliances, electronic components, and consumer products with intricate designs and aesthetic appeal.

Our Commitment to Excellence

At Custom Mold Services, excellence is at the core of everything we do. We invest in state-of-the-art manufacturing technology, ongoing employee training, and continuous improvement initiatives to ensure that we deliver superior manifold solutions that exceed customer expectations.

Choosing Custom Mold Services means partnering with a trusted leader in Manifolds for Plastic Injection Molding. Whether you are looking to optimize production efficiency, improve part quality, or reduce manufacturing costs, our dedicated team is ready to collaborate with you to achieve your goals.

Contact Us Today

Ready to explore how our Manifolds for Plastic Injection Molding can benefit your operations? Contact us today to speak with one of our knowledgeable team members. We are committed to providing customized solutions that meet your specific injection molding needs and drive success in your industry.

At Custom Mold Services, we are committed to setting the standard for precision and efficiency in injection molding with our advanced manifold solutions. Contact us today to learn more about how we can support your manufacturing goals with our expertise and innovation.